JICAM Pacific / JICAM North America

Slugs are precision, cold-formed, semi-finished parts that enable customers to reduce costs through material savings, shorter manufacturing times, prolonged tool life and less logistical costs. The slug configurations are carefully designed for optimal shape, then annealed and coated ready for the next manufacturing process.

For especially critical parts a PAQ (Perfect Assurance Quality) eddy current system is applied to guarantee that no parts have a surface defect deeper than 0.07mm (0.003”) or length longer than 5mm (0.197”)

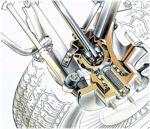

Inner Joint

Customer Benefits

-

✴ Reduced overall cost

-

✴ Less wastage of material

-

✴ Hardening process eliminated

-

✴ Zero defects (using PAQ system)

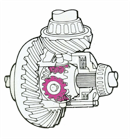

Differential Pinion Gear

Customer Benefits

-

✴ Reduced overall cost

-

✴ Less wastage of material

-

✴ Hardening process eliminated

-

✴ Reduced manufacturing time

-

✴ Zero defects (using PAQ system)

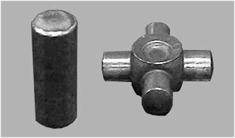

Steering Joint (Spider)

Customer Benefits

-

✴ Accurate weight 51.0g +/- 0.25g

-

✴ Consistent form reduces cost

Slugs (Precision Semi-Finished Parts)